It’s time for a HPGe repair! This one was broken and needed a new JFET. The detector itself is not mine, but a friends Canberra GC1520 on a portable Big MAC Dewar. It came from eBay, that’s all we know about it. It looks to be in good condition, but the endcap was bent inwards, like it got a strong blow from the front. Electrically it was dead, with a constant +12 V output, zero microphonics and no reaction to any kind of test signal.

This made it clear to me that the front end JFET was dead, so I went ahead to swap it. I set up the detector on my pump and opened the plug, which made the pressure immediately jump to a few 10s of mBar, showing significant pressure inside the cryostat. Most datecodes on the Preamplifier hint to the detector being made in the early ’90s, and judging from the pressure inside my guess is that it never had any maintenance done before, or it has a leak somewhere.

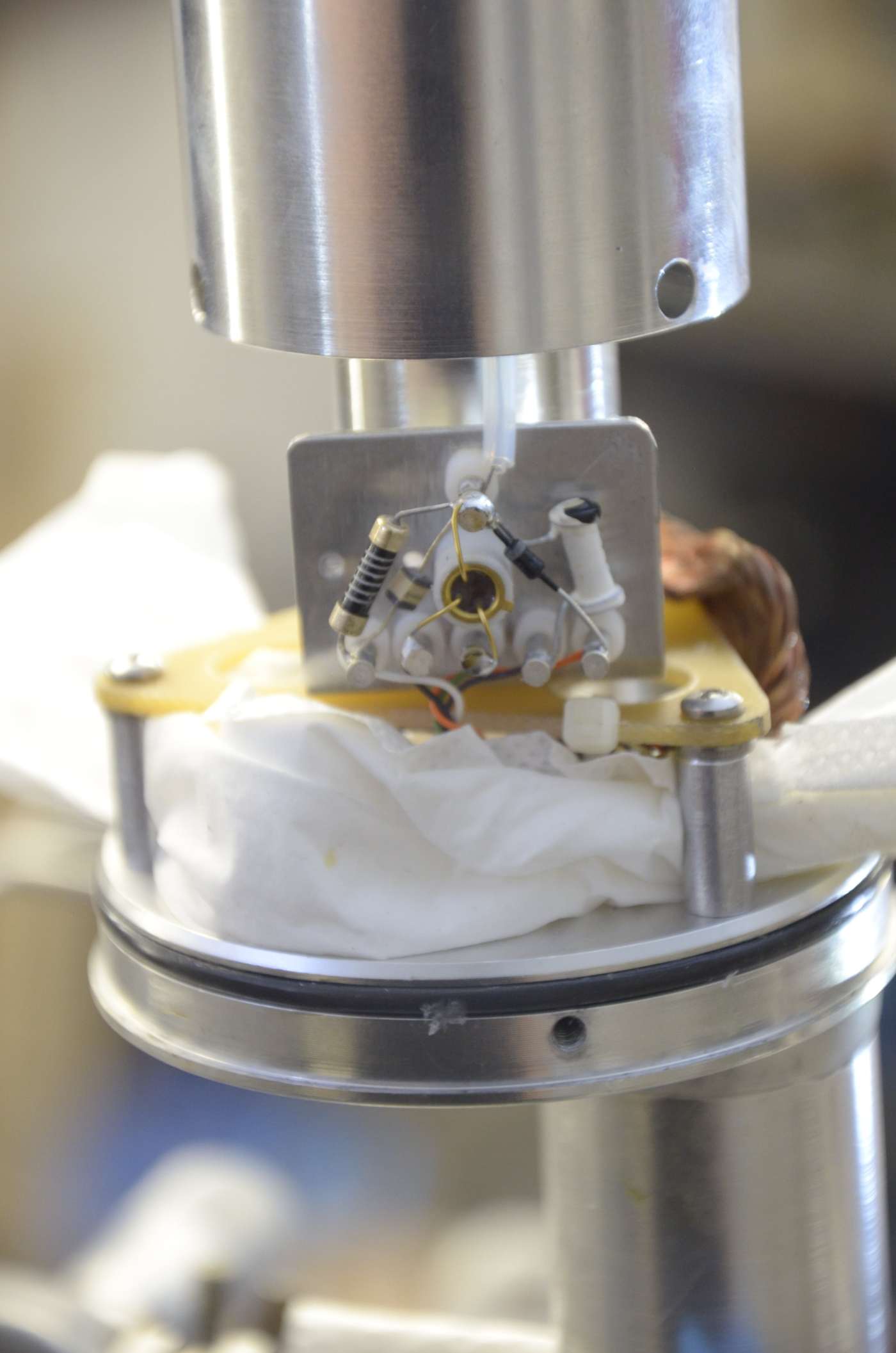

I evacuated the cryostat until my pirani bottomed out at 1E-3 mBar, backfilled it with Argon to flush residual air and repeated that two more times. After the last flush I opened up the detector endcap and had a small, but constant Argon stream into the dewar in order to keep it at positive pressure and displace some air where possible. The inside of the cryostat looked pretty ok, showing an older design of crystal holder and thermal isolation pad, but nothing to worry about. I quickly located the JFET and snipped off its legs to avoid introducing dirt and thermal issues due to unnecesary soldering. Sadly the name and all other text on the JFET was missing, so I had to gamble on the pinout. As a replacement I used a 2N4391, which is not ideal in terms of noise, but entirely adequate. As Carl Willis has shown the JFET isn’t as critical as one might think, and even with a “cheapo” audio JFET and still get a very respectable resolution. Since the gate matched on both pinouts I decided to replace it as is, and as it turned out that was the right call.

Out with the old, in with the new!

After swapping the JFET I cleaned up the solder joints with a toothbrush and some brake cleaner, isopropanol and lastly some pure ethanol without any added bittering agents. It is very important to keep the cryostat very clean, as any outgassing will cause a local pressure rise and might result in a high voltage breakdown, which will definitely kill the fet again.

The crystal itself is protected by a thin metal plate, held by some PTFE tape. The plate showed some scorch marks, and the endcap had the fitting counterparts on inside. I think it’s fair to assume, that the bad vacuum combined with reduced distance between the metal plate and endcap resulted in some arcs, which killed the fet. I applied some more PTFE tape to prevent further issues, as well as bending the endcap out again to regain some isolation distance.

Once I was done with these repairs I evacuated the dewar again, flushed a few times with argon and then closed it up again. With the preamplifier reinstalled it was time to test the detector, and it showed a beautiful output to the applied test signal, as well as the expected microphonics when tapping it!

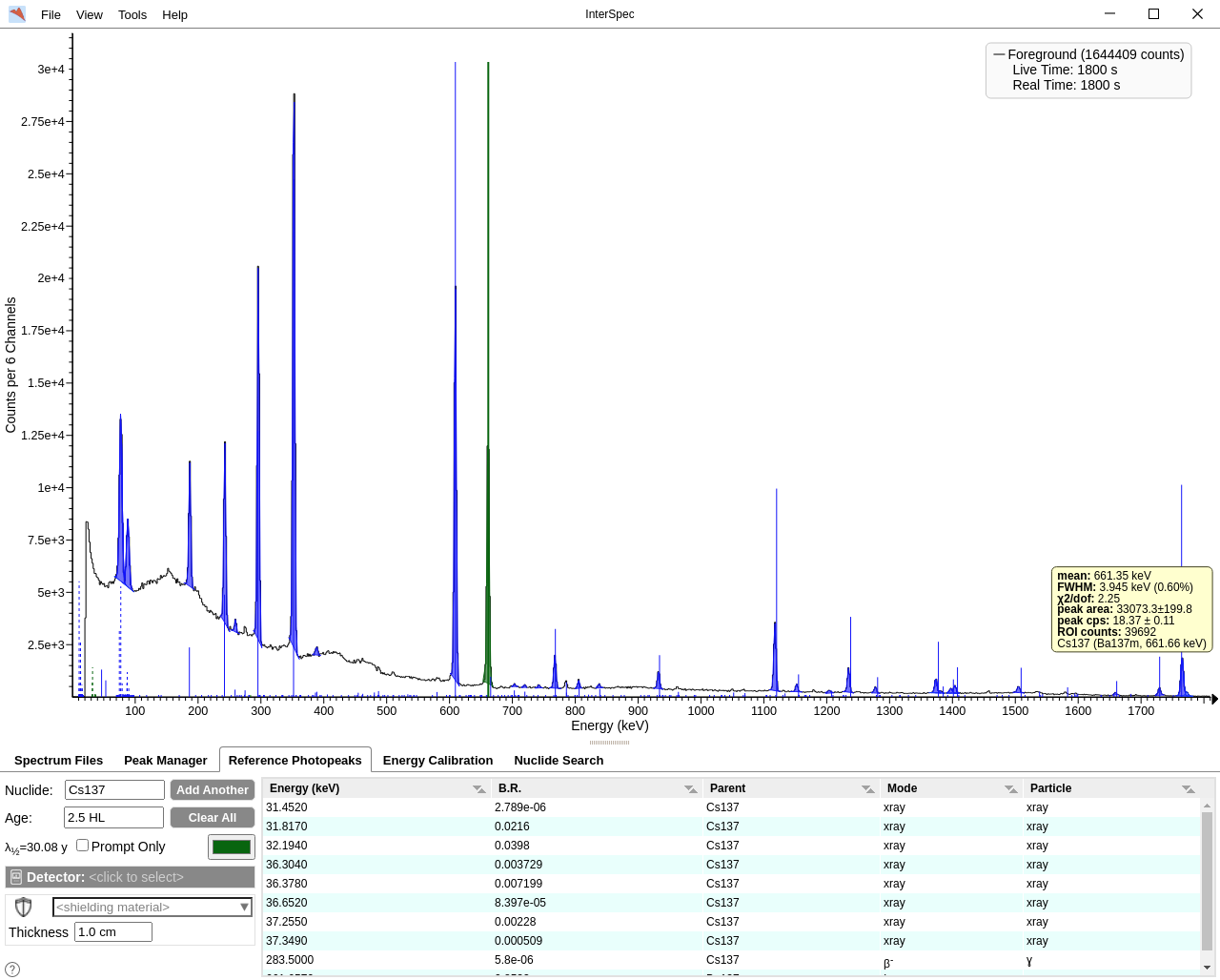

After finally acquiring some liquid nitrogen to test the detector I am happy to report that it is fully operational again! It cooled down nice and quick and reported operational temperature after around 2 hours. I then applied the bias voltage and got nice, clean pulses. It’s been ~2 weeks since I evacuated the dewar and it didn’t show any signs of condensation during the cooldown, so it’s fair to assume that it doesn’t have a major leak.

It appears that the crystal has suffered a bit, as even after a long cooling time it becomes very leaky and noisy above 3.5 kV, compared to the rated 4.0 kV on the specsheet. This is a small loss, as detectors are usually spec’d for far above the depletion voltage, so 500 V less won’t change much. All in all it still gives a very respectable FWHM of 4 keV at 662 keV, and I’m calling this repair a success.

After working with scintillators for the least year or so it was really nice to go back to semiconductor detectors, and I enjoyed this work a lot.

This is an abridged version of the original article on my website:

https://gigabecquerel.wordpress.com/202 ... -ever-was/

Feel free to ask any questions you have, and I hope you enjoyed reading this!

Lukas